Opto Payload Manufacturing Engineer

Acton, Massachusetts

Overview

General Atomics pioneers technologies with the potential to change the world. Behind a talented global team of engineers, GA delivers safe, sustainable, and economical solutions to meet growing global demands. Our Engineers have an opportunity to work on first of a kind product lines within an incredible, dynamic environment.

Engineering positions typically require a bachelor’s degree, master’s degree or PhD in engineering or a related technical discipline from an accredited institution and progressive engineering experience. Candidates from mechanical, electrical, and aerospace engineering backgrounds must know the fundamentals of engineering system developments, requirements, testing, and integration before getting to the final stages of customer interface and project management.

Schedule: Full-Time Salary

Job Level: Senior (8+ years)

Travel: 0 - 25

Success Profile

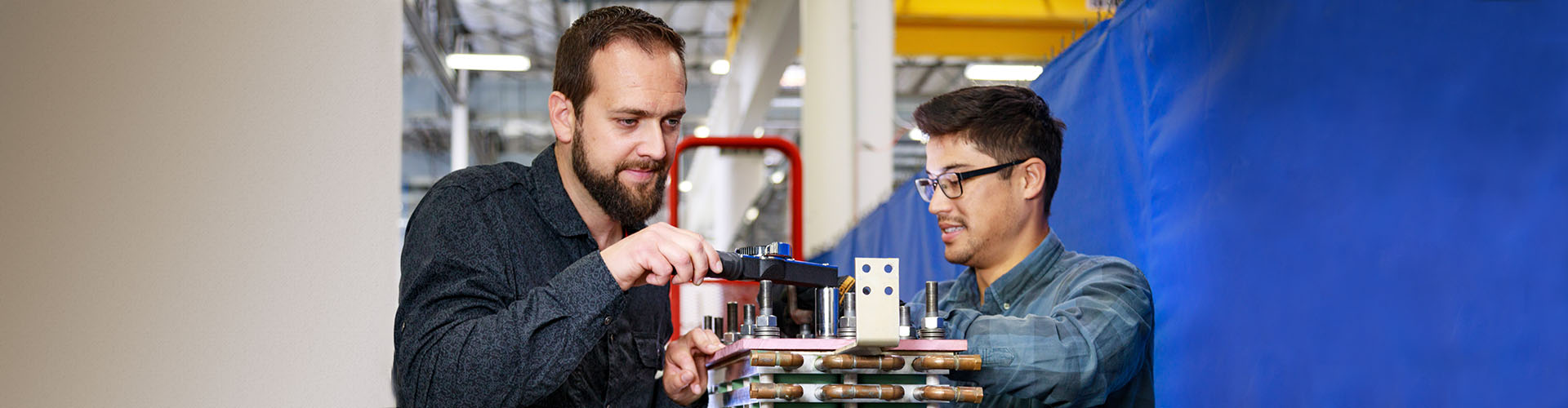

What makes a successful Opto Payload Manufacturing Engineer at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Analytical

- Collaborative

- Inventive

- Problem Solver

- Team Player

- Creative

Job Summary GA’s Electromagnetic Systems (EMS) Group focuses on the military and commercial applications of advanced electromagnetic technologies, including power generation and distribution, magnetic levitation, laser and weapons systems, and systems design and engineering. The EMS Group supports government customers, which include the Department of Defense, Department of Energy, the Department of Transportation as well as a range of commercial customers.

We have an exciting opportunity for an Optical Payload Manufacturing Engineer to join our team in Acton, MA!

With limited direction, this position is responsible for supporting the manufacturing production process of Optical systems and Optical Space Payloads to ensure they meet the mission requirements, while focusing on manufacturing, integration and testing, of parts, components, sub-assemblies, and final assemblies.

DUTIES AND RESPONSIBILITIES:

- Lead and execute manufacturing engineering activities for the assembly, integration and test of opto-mechanical systems

- Knowledge of how electro-optical and opto-mechanical systems are designed, developed, manufactured and tested

- Develops, implements, and maintains methods, operation sequence and processes in the manufacture or fabrication of optical parts, components, sub- assemblies, and final assemblies.

- Provide optical and opto-mechanical engineering support to the manufacturing technicians.

- Capable of Hands On Assembly and Test of Opto-Mechanical systems.

- Conducts tests throughout all stages of production to determine control over applicable variables and troubleshooting and resolving the most highly technical and complex manufacturing problems, requiring an exceptional degree of ingenuity, creativity, and resourcefulness.

- Recommends and designs the sequence of production operations, specifying procedures for the fabrication of applicable tools and equipment, and adapting machinery in response to factory conditions.

- Collaborates with cross functional teams in coordinating manufacturing optical systems

- Provides leadership, direction, and guidance for developing solution to manufacturing engineering problems.

- Advises design engineering on technical specifications that will best utilize equipment and manufacturing techniques.

- Estimates manufacturing cost, determines time standards, and makes recommendations for tooling and process requirements of new or existing product lines.

- Ensures that production processes and procedures are in compliance with regulations.

- Plans for future applications of solutions based on new developments in manufacturing technology.

- Plans and coordinates the maintenance of manufacturing engineering solutions including, documentation, reporting, and making technical and other presentations to ensure viability of the solution(s) in an evolving environment.

- Participates in or directs the allocation of technical resources and professional staff to achieve objectives.

- Ability to obtain and maintain a DoD Secret Clearance

- Maintains the strict confidentiality of sensitive information.

- Performs other duties as assigned.

- Responsible for observing all laws, regulations, and other applicable obligations wherever and whenever business is conducted on behalf of the Company.

- Expected to work in a safe manner in accordance with established operating procedures and practices.

Job Qualifications:

- Typically requires a bachelors in engineering or a related technical field as well as fourteen or more years of manufacturing engineering experience. May substitute equivalent experience in lieu of education.

- Applies advanced technical manufacturing engineering principles, concepts, theory, and practice as well as project and/or program leadership including organizing, planning, scheduling, and coordinating workloads to meet established project deadlines or milestones.

- Must possess the ability to contribute to the development of new concepts and principles; resolve unusually complex technical problems; serve as spokesperson on projects and/or programs; and be a technical expert in one or more areas of engineering.

- Strong communication, presentation, and interpersonal skills are required enabling an effective leadership interface with other departments, all levels of management, professional and support staff, customers, potential customers, and government representatives.

- Customer focused, formulates plans based on the development of innovative new designs in resolving advanced technical engineering problems.

- Must be able to work on a self-initiated basis and in a team environment.

- Able to work extended hours as required.

Salary:$116,480 - $208,505

Benefits

-

Healthcare

-

Pension, 401(k)/Retirement Plans

-

Competitive Pay

-

Multiple product lines means a variety of work

-

Paid Time Off

“The company is growing, has a very good reputation and had open positions in my area of expertise (aircraft design/design methodology development).”– Peter, Senior Staff Engineer

“We don't ascribe to quotas; we do ascribe to securing the BEST talent to enrich our culture toward healthy diversification and active/viable community service. We are STEM advocates.”– Debra, CSSBB: Staff Engineer

“Every day is different, with different problems to solve and many programs to support. I am a problem solver and have always been motivated by the tough questions.”– Scott, Laser Scientist

“I work in the Components Engineering and Obsolescence Management Dept. Our efforts are saving General Atomics several millions of dollars by proactively leading and informing the company of all these decisions which significantly impact production, sustainment and new designs.”– John, Staff Engineer

News

-

Featured Jobs

- Senior Staff Autonomy Stack Architect Poway, California

- Legal Assistant San Diego, California

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Senior Staff Autonomy Stack Architect Poway, California

- Legal Assistant San Diego, California

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Senior Staff Autonomy Stack Architect Poway, California

- Legal Assistant San Diego, California

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.