Composite Technician Assembler

Adelanto, California

Overview

Assemblers, Machinists, Material and Production Control, Composite Technicians, Coordinators, Planners and Stock Clerks. These are just a few of the Manufacturing positions we offer at General Atomics. As a Manufacturing team member, you will use high-tech machines, systems, equipment and tools to create and build our products.

Experience in handling composite materials, using CNC machines and software, reading blueprints and drawings and a general understanding of manufacturing prinicples and systems are all desirable qualifications.

Schedule: Full-Time Hourly

Job Level: Mid-Level (3-7 years)

Travel: 0 - 25

Success Profile

What makes a successful Composite Technician Assembler at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Detail Oriented

- Team Player

- Results Driven

- Organized

- Productive

- Problem Solver

Job Summary General Atomics Aeronautical Systems, Inc. (GA-ASI), an affiliate of General Atomics, is a world leader in proven, reliable remotely piloted aircraft and tactical reconnaissance radars, as well as advanced high-resolution surveillance systems.

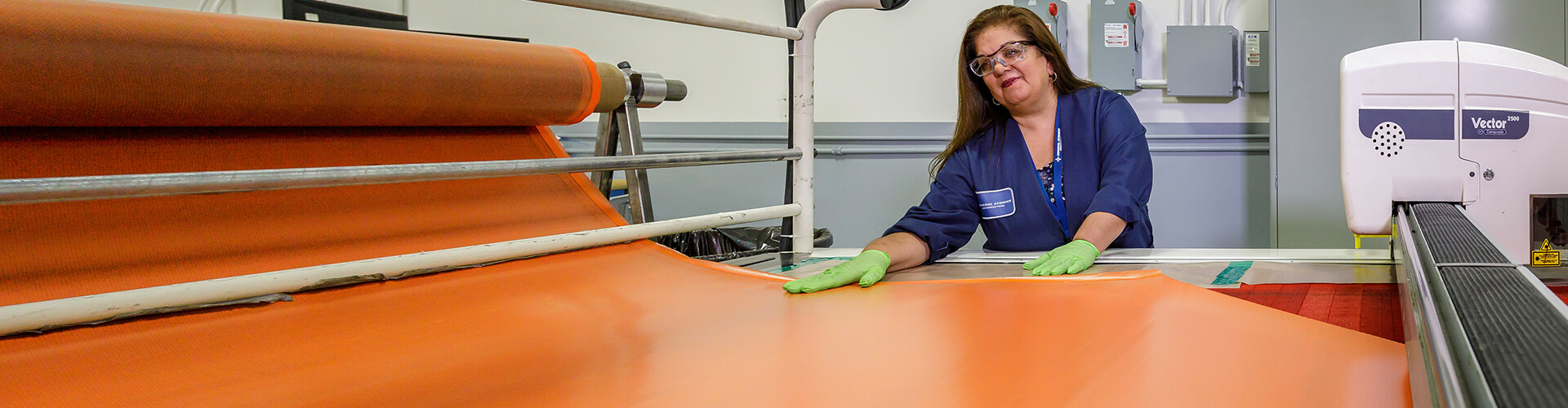

Under limited supervision and working in a loud environment with a variety of epoxy agents, this position performs a variety of non-routine and non-repetitive procedures and assists in the fabrication, curing, build-up and assembly of various types of composite materials where required information is readily available, methods and sequences have been pre-determined and tooling is provided. Works to blueprints, templates, sample parts, process sheets and other authorized information.

DUTIES AND RESPONSIBILITIES:

- Assist in the preparation of molds and forms.

- Mark and cut tape, woven material, honeycomb, adhesive and similar materials following templates, guides or specific dimensions and sequences.

- Route, drill, trim, and install fasteners to blueprint dimensions and tolerances. Operate vacuum press as required. Assist in the lay-up of composite materials to molds.

- Fit and smooth successive layers of materials as necessary to secure build-up free from wrinkles, air pockets and voids following directions and instructions.

- Assist in the development of shop aids to facilitate fabrication, trimming and assembly as required.

- Assemble Aircraft components using structural adhesives, rivets and threaded fasteners.

- Prepare surface and paint composite and metal components including bodywork, contour shaping and sanding. Apply spray application of epoxy paints, urethane and water based epoxy coatings, using a high volume low-pressure spray gun.

- Check expiration dates of materials prior to use, prepare proper mixes of resins and catalysts.

- May make continuity checks on work in progress and may monitor and verify quality in accordance with statistical process or other control procedures.

- Maintain records as required. Supports the quality process by maintaining work area in an orderly condition by returning tools, equipment and materials to storage areas.

- Responsible for observing all laws, regulations and other applicable obligations wherever and whenever business is conducted on behalf of the Company.

- Expected to work in a safe manner in accordance with established operating procedures and practices. Additional Functions: Other duties as assigned or required.

- Ability to work independently as well as in a team environment.

We recognize and appreciate the value and contributions of individuals with diverse backgrounds and experiences and welcome all qualified individuals to apply.

Job Qualifications:

- Typically requires High School diploma or equivalent and seven or more years of related experience.

- Must be able to verbally communicate, read and comprehend written and verbal instructions, detailed blueprints and other similar authorized drawings and documents, and be capable of doing basic mathematical calculations.

- Must be able to use hand tools, such as rollers, paper cutters, scissors, x-acto knives, electric heat gun and fixtures such as molds and mandrels.

- Ability to use measuring instruments such as scales and protractors and calipers.

- Familiarity with common shop tools such as band saws, disk sanders, drill press, wood lathe, etc.

- May require respirator certification.

- Must be able to work in a loud environment; work extended hours as required; and be able to lift assemblies weighing up to 50 lbs.

Salary:$65,410 - $99,888

Benefits

-

Competitive Pay

-

Paid Time Off

-

Healthcare

-

Multiple product lines means a variety of work

-

Pension, 401(k)/Retirement Plans

-

Travel

“The people I work with and the great opportunities to grow are the reasons I look forward to coming to work every day.”– Ralph, Technician

“I enjoy working with good people and knowing I am helping our great military.”– Joe, Fabricator

“I chose General Atomics because I wanted to work in a challenging work environment.”– Tony, Composite Technician

“I'm excited to come to work because of the new projects and challenges.”– James, Quality Composite Inspector

News

-

Featured Jobs

- Senior Staff Autonomy Stack Architect Poway, California

- Legal Assistant San Diego, California

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Senior Staff Autonomy Stack Architect Poway, California

- Legal Assistant San Diego, California

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Senior Staff Autonomy Stack Architect Poway, California

- Legal Assistant San Diego, California

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.